It’s A Technicolour Dreamcoat For Your Crisp Packet – A Strong, Flame-retardant And Airtight New

It’s a technicolour dreamcoat for your crisp packet – a strong, flame-retardant and airtight new material that mimics mother of pearl.

The natural version, also called nacre, is found on the inner shell of some molluscs, where it is built up of layers of the mineral aragonite separated by organic polymers such as chitin. It is remarkably strong, without being brittle or dense.

We would like to use nacre and similar materials as a protective coating in many situations. However, making them is a slow and delicate process that is difficult to recreate at any useful scale. Artificial nacre-like materials are usually painstakingly built up layer by layer, but Luyi Sun at the University of Connecticut in Storrs and his colleagues found a way to do it all in one go.

Continue Reading.

More Posts from T-sci-eng and Others

Thought this was important to post.

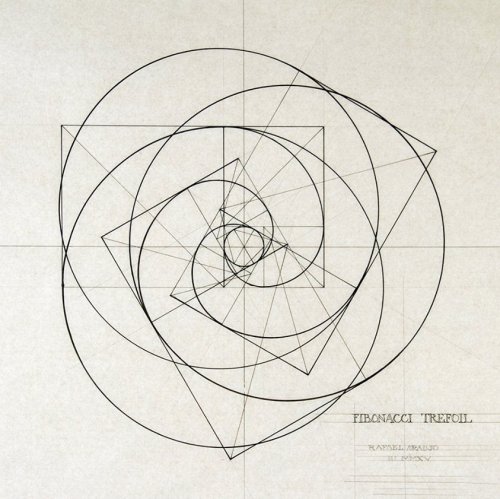

Fibonacci trefoil

© Rafael Araujo

Alloys: Wood’s Metal

Also known as Lipowtiz’s alloy as well as the commercial names of Cerrobend, Bendalloy, Pewtalloy, and MCP 158 among others, Wood’s metal is a bismuth alloy consisting of 50% bismuth, 26.67% lead, 13.33% tin, and 10% cadmium by weight. Named for the man who invented it, a Barnabas Wood, Wood’s metal was discovered/created by him in 1860.

Wood’s metal is both a eutectic and a fusible alloy, with a low melting temperature of approximately 70 °C (158 °F). While none of its individual components have a melting temperature of less than 200 °C, a eutectic alloy can be considered as a pure (homogeneous) substance and always has a sharp melting point. If the elements in a eutectic compound or alloy are not as tightly bound as they would be in the pure elements, this leads to a lower melting point. (Eutectic substances can have higher melting points, if its components bind tightly to themselves.)

Useful as a low-temperature solder or casting metal, Wood’s metal is also used as valves in fire sprinkler systems. Thanks to its low melting temperature, Wood’s metal melts in the case of a fire and thanks to the bismuth it is made from, the alloy also shrinks when it melts (bismuth, like water ice, is one of the few substances to do so) which is the key to setting off the sprinkler system. Wood’s metal is also often used as a filler when bending thin walled metal tubes: the filler prevents the tube from collapsing, then can be easily removed by heating and melting the Wood’s metal. Other applications include treating antiques, as a heat transfer medium in hot baths, and in making custom shaped apertures and blocks for medical radiation treatment.

With the addition of both lead and cadmium, however, Wood’s metal is considered to be a toxic alloy. Contact with bare skin is thought to be harmful, especially once the alloy has melted, and vapors from cadmium containing alloys are also quite dangerous and can result in cadmium poisoning. A non-toxic alternative to Wood’s metal is Field’s metal, composed of bismuth, tin, and indium.

Sources: ( 1 - image 4 ) ( 2 - image 2 ) ( 3 ) ( 4 )

Image sources: ( 1 ) ( 3 )

Vantablack absorbs 99% of light and is the darkest material ever made.

Does one of these LEGO men look bigger than the other? They’re actually the exact same size, but are in an Ames room - a false-perspective illusion room that tricks your brain into thinking things are smaller, or larger, than they really are.

You can make one of these models to try this for yourself. Download our free template from here. And it even works in full size, if you can make one large enough!

Elevated Bus That Drives Above Traffic Jams

Impressive artwork.

Dr. Greg Dunn (artist and neuroscientist) and Dr. Brian Edwards (artist and applied physicist) created Self Reflected to elucidate the nature of human consciousness, bridging the connection between the mysterious three pound macroscopic brain and the microscopic behavior of neurons. Self Reflected offers an unprecedented insight of the brain into itself, revealing through a technique called reflective microetching the enormous scope of beautiful and delicately balanced neural choreographies designed to reflect what is occurring in our own minds as we observe this work of art. Self Reflected was created to remind us that the most marvelous machine in the known universe is at the core of our being and is the root of our shared humanity.

h-t New Scientist: Brain images display the beauty and complexity of consciousness

Students fortify concrete by adding recycled plastic

Adding bits of irradiated plastic water bottles could cut cement industry’s carbon emissions

Discarded plastic bottles could one day be used to build stronger, more flexible concrete structures, from sidewalks and street barriers, to buildings and bridges, according to a new study.

MIT undergraduate students have found that, by exposing plastic flakes to small, harmless doses of gamma radiation, then pulverizing the flakes into a fine powder, they can mix the plastic with cement paste to produce concrete that is up to 20 percent stronger than conventional concrete.

Concrete is, after water, the second most widely used material on the planet. The manufacturing of concrete generates about 4.5 percent of the world’s human-induced carbon dioxide emissions. Replacing even a small portion of concrete with irradiated plastic could thus help reduce the cement industry’s global carbon footprint.

Reusing plastics as concrete additives could also redirect old water and soda bottles, the bulk of which would otherwise end up in a landfill.

Read more.

Møbius donut.

-

dismalchant liked this · 1 year ago

dismalchant liked this · 1 year ago -

briarhips liked this · 1 year ago

briarhips liked this · 1 year ago -

plumslices liked this · 1 year ago

plumslices liked this · 1 year ago -

fairiegardens liked this · 1 year ago

fairiegardens liked this · 1 year ago -

biomaterial reblogged this · 1 year ago

biomaterial reblogged this · 1 year ago -

artemisarticles reblogged this · 2 years ago

artemisarticles reblogged this · 2 years ago -

neuropteran liked this · 2 years ago

neuropteran liked this · 2 years ago -

ulualuut liked this · 2 years ago

ulualuut liked this · 2 years ago -

counter-intelligentsia liked this · 2 years ago

counter-intelligentsia liked this · 2 years ago -

oeutral liked this · 2 years ago

oeutral liked this · 2 years ago -

riversurface liked this · 2 years ago

riversurface liked this · 2 years ago -

662607015 liked this · 2 years ago

662607015 liked this · 2 years ago -

organicmatter liked this · 2 years ago

organicmatter liked this · 2 years ago -

biomaterial reblogged this · 2 years ago

biomaterial reblogged this · 2 years ago -

soleilcoucoupe reblogged this · 4 years ago

soleilcoucoupe reblogged this · 4 years ago -

soleilcoucoupe reblogged this · 4 years ago

soleilcoucoupe reblogged this · 4 years ago -

passengerpigeons liked this · 4 years ago

passengerpigeons liked this · 4 years ago -

rosesonmyshelf liked this · 4 years ago

rosesonmyshelf liked this · 4 years ago -

biomaterial reblogged this · 4 years ago

biomaterial reblogged this · 4 years ago -

artemisarticles reblogged this · 4 years ago

artemisarticles reblogged this · 4 years ago -

dearkurisu liked this · 6 years ago

dearkurisu liked this · 6 years ago -

nualie liked this · 6 years ago

nualie liked this · 6 years ago -

sugarbutchy reblogged this · 7 years ago

sugarbutchy reblogged this · 7 years ago -

pinkeebwui liked this · 7 years ago

pinkeebwui liked this · 7 years ago -

persephonedevoted reblogged this · 7 years ago

persephonedevoted reblogged this · 7 years ago -

persephonedevoted liked this · 7 years ago

persephonedevoted liked this · 7 years ago -

aspiringgaycowboy reblogged this · 7 years ago

aspiringgaycowboy reblogged this · 7 years ago -

aspiringgaycowboy liked this · 7 years ago

aspiringgaycowboy liked this · 7 years ago -

captain-acab reblogged this · 7 years ago

captain-acab reblogged this · 7 years ago -

marimbistchick reblogged this · 7 years ago

marimbistchick reblogged this · 7 years ago -

calicotomcat reblogged this · 7 years ago

calicotomcat reblogged this · 7 years ago -

augoldeverything reblogged this · 7 years ago

augoldeverything reblogged this · 7 years ago -

fatherizzyisms liked this · 7 years ago

fatherizzyisms liked this · 7 years ago -

unswsams reblogged this · 7 years ago

unswsams reblogged this · 7 years ago -

555-evil-gnomes reblogged this · 7 years ago

555-evil-gnomes reblogged this · 7 years ago -

ununnilium liked this · 7 years ago

ununnilium liked this · 7 years ago -

theorigamiphoenix liked this · 7 years ago

theorigamiphoenix liked this · 7 years ago -

dialmformara reblogged this · 7 years ago

dialmformara reblogged this · 7 years ago -

mountainpassers reblogged this · 7 years ago

mountainpassers reblogged this · 7 years ago -

fredscience-blog reblogged this · 7 years ago

fredscience-blog reblogged this · 7 years ago -

forgotn1 reblogged this · 7 years ago

forgotn1 reblogged this · 7 years ago